A circular economy approach could reduce carbon emissions from the global lithium-ion battery supply chain by as much as 35%, according to new research published in Nature by Yufeng Wu and colleagues. The study underscores that such a transition would require robust international cooperation and region-specific policy frameworks to be effective.

Rethinking the Carbon Cost of Lithium-Ion Batteries

Lithium-ion batteries are widely seen as a cornerstone of the renewable energy transition, powering electric vehicles, portable electronics, and renewable energy storage systems. Yet, their production and disposal carry a significant carbon footprint — one that can undermine their sustainability benefits if left unaddressed.

The research team analyzed carbon emissions at each stage of the lithium-ion battery supply chain — from mining raw materials to manufacturing, transport, and end-of-life recycling. Their goal was to pinpoint where emissions could be most effectively reduced.

Where Emissions Come From

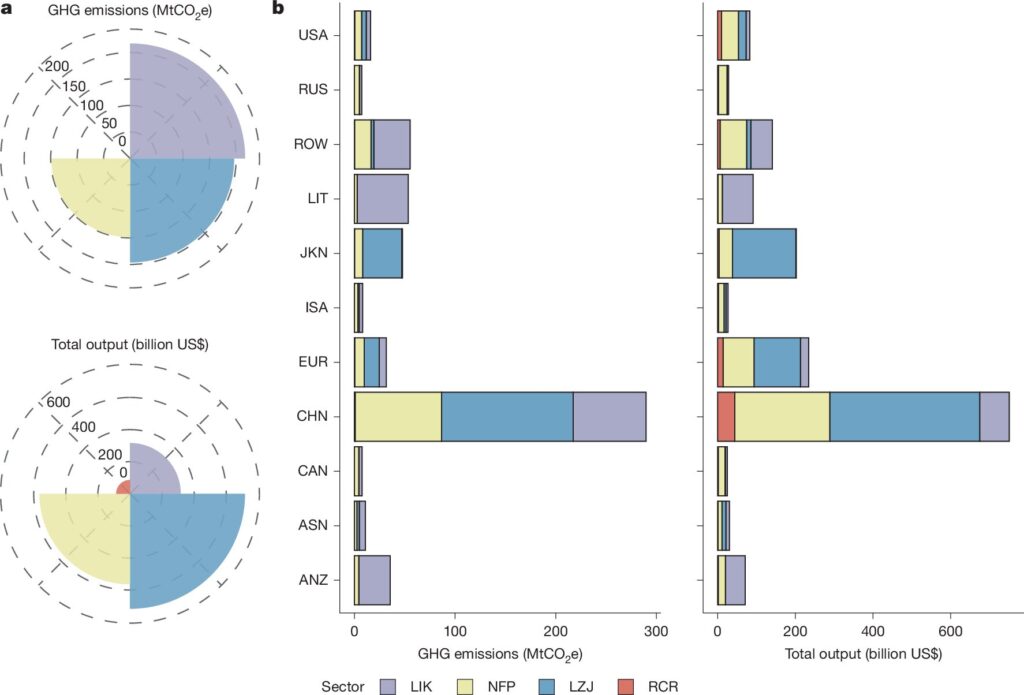

The study found that mining the raw minerals needed for batteries — such as lithium, nickel, and cobalt — is the single largest source of emissions, accounting for 38.52% of total emissions in the production process. Despite this heavy carbon toll, mining contributes only 18.78% of the total economic value of a finished battery.

This imbalance highlights what the authors call a “value–emission paradox”: stages of the supply chain that generate lower revenue tend to produce higher emissions.

In contrast, cathode production — a more value-intensive process — generates 42.56% of the battery’s economic value but contributes 34.82% of total emissions.

Circular Economy Strategies Offer Hope

To address this imbalance, Wu and colleagues modeled the potential benefits of a circular economy strategy. By recycling critical metals from used batteries and reintegrating them into new production cycles, they estimate that global emissions from lithium-ion battery manufacturing could be cut by an average of 35.87%.

Regionally, the reductions could reach 39.14% in the United States, 37.28% in the European Union, and 42.35% in China.

Cooperation and Equity Are Key

However, the researchers caution that this framework also raises questions of equity and benefit distribution. Some nations are likely to gain more economically from battery recycling and circular supply chains than others, given differences in industrial infrastructure and access to resources.

To ensure fairness and effectiveness, the authors argue that a circular economy for lithium-ion batteries must rest on robust international agreements, shared technological standards, and equitable trade and recycling policies.

Looking Ahead

As the global demand for electric vehicles and renewable energy storage continues to surge, the study suggests that a globally coordinated circular economy could significantly reduce emissions, conserve resources, and make the battery industry more sustainable. But without cooperation, the benefits may remain unevenly distributed — and the promise of a truly sustainable battery future may remain out of reach.

Source:

Yufeng Wu et al., Nature (2025). “Carbon emissions from the lithium-ion battery supply chain could be reduced by 35% through circular economy strategies and global cooperation.”

No responses yet